Mass loading your speaker stand for the optimum performance depends on two particle speaker stand design features. At Custom Design we have found here is a collation between the rigidity and the speaker stands performance. The second feature is Mass loading with Inert Filler and its dense, high mass value. When mass loading a speaker stand the important thing to remember is the initial mass of the stand its self. You can't just mass load a 4kg speaker stand with 13kg, the bass frequency timing and precision will be completely lost. Try not to mass load over the original the mass of the stand without Inert Filler applied.

There can be 3 types of speaker stand design, a lite mass which has laser cut out plates, minimal supports and as rigid as possible. This type of stand requires very little mass loading only to fine tune and control the bass frequency. This is your typical open frame speaker stand design like the HOS 505, QS 104 or the fully welded open frame speaker stands, usually 500g to 800g per support depending upon the height of your speaker stand.

The second design a Medium Mass speaker combines the rigidity of the open frame principle speaker with the ability to add more Inert Filler, generally around 3.5kg to 7kg per support, depending the height and model. This design speaker stand features acoustic steel isolation top plates either laser cut out or sometimes full acoustic steel top plates depending upon the speaker brand. The base plate can be laser cut out to minimise the initial mass of the speaker stand design, such as the FS 104 signature range and the OM speaker stands, Again, mass loading depends upon the speaker brand as some are mass sensitive and can destroy the original speaker characteristics. The Medium mass loading speaker stands offer a hybrid option, best of both Lite mass and High Mass features.

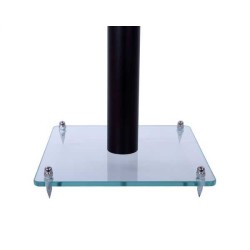

The third design is a high mass speaker stand with several supports which can be mass loaded, providing an acoustic sinc for the speaker cabinet. But only a select range can benefit from the high mass principle, those which require help from the speaker stand to produce a better bass frequency. These speaker stands generally have 4mm full acoustic steel top plates, 6mm CR4 steel base plates with large support columns allowing the addition of easily 13kg to 20kg Inert Filler, per speaker stand, for mass loading, designs like the RS 304 XL, ATC SCM100, the Dutch and Dutch SQ 404, FS 106 and the FS 108s. These speaker stand designs in the opinion of Custom Design tent to push the bass frequency more..

Speaker Stands Custom Design Harbeth Speaker Stand Supports Kef LS50 Speaker Stands ATC Speaker Stands Harbeth P3 Speaker Stands Spendor Speaker Stands Custom Height Speaker Stands Custom made Speaker Stands HiFi Isolation Platform Speaker Stands Acoustic Steel Isolation Constrained Layer Dampening Isolation Top Plates Award Winning FS 104 Signature Speaker Stands Dutch & Dutch Speaker Stands RS 300 Speaker Stands SQ 404 Speaker Stands Open Frame Speaker Stands Mass Loading Speaker Stands Polished Chrome Speaker Stands Wood Speaker Stands ATC SCM11 Speaker Stands Custom height Brushed Chrome Speaker Stands Wooden Speaker Stands Fully welded open Frame Speaker Stands Inert Filler Specialist Mass Loading Speaker Stand material RS 200 Speaker Stands FS 106 Speaker Stands FS 108 Speaker Stands