Custom Design, exclusive Inert Filler, Specialist Speaker Stand Mass Loading Dampening Material, very dense at 13kg per box and manufactured in accordance with quality management system complying with ISO 9001 U K A S 0006 Lucid On. Speaker Stand Support Resonance Dampening material, Inert Filler is an Exclusive Brand name and product to Custom Design. Inert Filler is a brand name Copyright © to Custom Design (Newcastle) 1994. Very Dense, Speaker Stand Mass Loading Material Inert Filler 13kg per box, very dense, speaker stand, mass loading specialist material with a very heavy mass application, 13kg per box, 1.7kg per bag approximately and perfect for speaker stand mass loading. Speaker stand Dampening Material Inert Filler and is a product which has been manufactured in accordance with a quality management system complying with ISO 9001 U K A S Management System 0006 Lucid On.

Atacama Atabites Inert Filler Is Not An Official Custom Design Product. Inert Filler is an exclusive Specialist Speaker Stand Mass Loading Dampening Material Inert Filler Copyright Product Brand Inert Filler To Custom Design For 26 Years. Exclusive Inert Filler Specialist Speaker Stand Dampening Material Angular 1mm to 2mm Particles Dissipates Voids Inside Speaker Stand Support Columns Easy Application No Rusting 1.7kg per bag - 8 bags per box 13.5kg approximately. Highly Recommended For Custom Design Speaker Stands Dampening Material Inert Filler. Volume Required Depends on Initial Mass Of Speaker Stand Diameter Of Support Columns.

The benefits of Inert Filler and mass loading speaker stand support column(s) will be to enhance the performance of your speakers and the speaker stand support. Custom Design only recommend the use of the official Inert Filler with all of the products manufactured by Custom Design. Highly recommended for speaker Stands and Centre Channel Speaker Stands, the volume required of the specialist Dampening Material Inert Filler depends upon the Initial Mass Of speaker support and the diameter and length of support columns.

Inert Filler, Mass loading and dampening the centre support column(s) is an important initial upgrade. Once mass loaded to our recommended amount, the performance will be particularly noticeably to the bass frequencies, with a more controlled and precision timing to the bass frequency. If you feel the bass still requires enhancing and control then add a little more Inert Filler.

For over 26 years Custom Design have recommended only Inert Filler for all of the speaker stand designs. With constant research and development we have not found a more appropriate speaker stand resonance dampening material. At twice the mass weight of Atacama Atabites and a completely different material, Custom Design Inert Filler is not only a better value speaker stand specialist mass loading material, different particle dimensions, different colour, none resonant and will not rust.

Inert Filler is a specially sourced material for dampening speaker stand support column(s). The particle size of 1mm to 2mm with angular features provides an ideal material for applying, perfect for eliminating voids in support columns and providing perfect very dense, high mass loading for speaker stand supports.

Inert Filler is an inert material, none resonant, none magnetic with the very dense consistency and angular particle size. These angular shapes help prevent and eliminate the presence of voids (pockets of air) occurring inside the support column(s), eliminating as much as possible of the air inside the support column and dampening any possible resonance influence from the speaker stand support column(s).

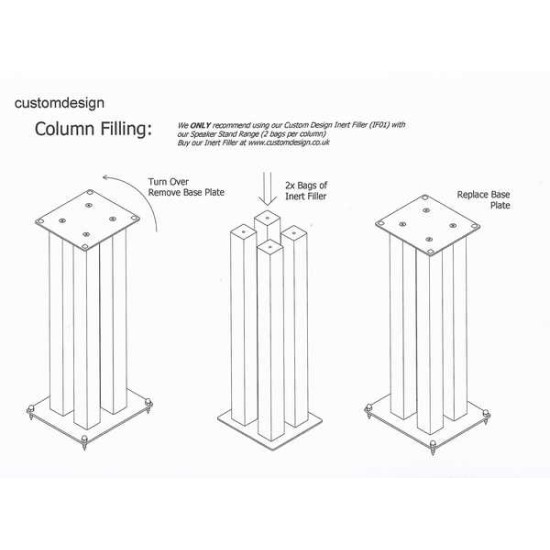

As a simple guide to follow, Custom Design recommend at least 2 bags of Inert Filler per 600mm column if it is not supplied as standard. Please be aware that we have found over mass loading can have a detrimental effect on the performance of your speaker, removing any benefit especially to the bass frequency timing and precision. If the bass frequency requires more control then please add Inert Filler in 100g increments

The advantages of Inert Filler, supplied in dry individual sealed bags or boxes of 8, is a none magnetic material, a none resonant material, will not rust, is not a waste product and application is simple. Perfect for dampening speaker stand support column(s) and easy to apply.

Custom Design sources all cardboard packaging from only PEFC or FSC certified companies. 76% of the cardboard packaging has been manufactured from recycled material which can be 100% recycled.

There is only one Custom Design Inert Filler, Atabites try to imitate, try to copy, look nothing like Inert Filler and manufactured from steel, resonate inside the speaker stand support.

Inert Filler is a Very Dense, Speaker Stand, Mass Loading Material with a Very High mass value and easy application process.

Inert Filler eliminates voids from occurring in the speaker stand support column and is a certified management System ISO 9001 Product U K A S Management System product.

Inert Filler is none resonant, none rust, none magnetic, Inert material, perfect for mass loading speaker stands.

Inert Filler with 1mm to 2mm particle size provides easy application. Atacama Atabites are much larger

Inert Filler is not manufactured from steel and will not resonate in steel speaker stand supports like Atacama Steel Atabites

Inert Filler per box contains 8 bags £39.99 Approximately 13kg much better value than the equivalent Atacama Atabites at only 7kg

Inert Filler Per bag £5.99 Approximately 1.7kg 4 bags nearly the same weight as Atacama Atabites

Inert Filler Packaging manufactured from 76% recycled material and 100% recyclable Atacama Atabites uses a Plastic container

Inert Filler does exactly stated on the packaging, provides perfect mass loading material for Hifi Furniture and speaker stand supports, Atacama Atabites doesn't even mention Inert Filler on the packaging?

Inert Filler is small in particle size ans easy to mass load speaker stands, Atacama Atabites with the large variation in particle size cannot and should not be used with Custom design Speaker Stands if you require the best performance from your speakers.

Mass loading your speaker stand for the optimum performance depends on two particle speaker stand design features. At Custom Design we have found here is a collation between the rigidity and the speaker stands performance. The second feature is Mass loading with Inert Filler and its dense, high mass value. When mass loading a speaker stand the important thing to remember is the initial mass of the stand its self. You can't just mass load a 4kg speaker stand with 13kg, the bass frequency timing and precision will be completely lost. Try not to mass load over the original the mass of the stand without Inert Filler applied.

There can be 3 types of speaker stand design, a lite mass which has laser cut out plates, minimal supports and as rigid as possible. This type of stand requires very little mass loading only to fine tune and control the bass frequency. This is your typical open frame speaker stand design like the HOS 505, QS 104 or the fully welded open frame speaker stands, usually 500g to 800g per support depending upon the height of your speaker stand.

The second design a Medium Mass speaker combines the rigidity of the open frame principle speaker with the ability to add more Inert Filler, generally around 3.5kg to 7kg per support, depending the height and model. This design speaker stand features acoustic steel isolation top plates either laser cut out or sometimes full acoustic steel top plates depending upon the speaker brand. The base plate can be laser cut out to minimise the initial mass of the speaker stand design, such as the FS 104 signature range and the OM speaker stands, Again, mass loading depends upon the speaker brand as some are mass sensitive and can destroy the original speaker characteristics. The Medium mass loading speaker stands offer a hybrid option, best of both Lite mass and High Mass features.

The third design is a high mass speaker stand with several supports which can be mass loaded, providing an acoustic sinc for the speaker cabinet. But only a select range can benefit from the high mass principle, those which require help from the speaker stand to produce a better bass frequency. These speaker stands generally have 4mm full acoustic steel top plates, 6mm CR4 steel base plates with large support columns allowing the addition of easily 13kg to 20kg Inert Filler, per speaker stand, for mass loading, designs like the RS 304 XL, ATC SCM100, the Dutch and Dutch SQ 404, FS 106 and the FS 108s. These speaker stand designs in the opinion of Custom Design tent to push the bass frequency more..

Image: Box of Inert Filler containing 8 bags Inert Filler

Image: 2 Bags of Inert Filler approximately 1.7kg per bag and 2 bags recommended to mass load a 76mm dia: speaker stand support 610mm high

Image: Inert Filler, Black material, 1mm to 2mm particle size, kills voids inside the stand support column perfect material for mass loading specialist hifi furniture

Image: Inert Filler Mass Loading instruction sheet for the SQ 404 speaker stand range, the volume of Inert Filler required is determined by the height of the support column and the of bass frequency control preference of each individual customer.

Custom Design only recommend the official Inert Filler for mass loading with all of the speaker stand support range.

HiFi Furniture HiFi Supports HiFi Tables HiFi Stands Speaker Stands

- Model: IF201